Hey everyone. This is going to be my build thread for my 2001 Silver Insight. I plan to modify almost every aspect of the car in search of the ultimate Insight cruiser/Track Toy.

The goal of this project are as follows;

- 12.50 1/4 mile times

- 50-55 MPG on highway trips

- 1G skid pad handling on street tires (RS-3, StarSpecs, Rivels)

- Long distance driving in comfort

- Well integrated Infotainment center

- A/C, Heat, ABS, Power steering are all required.

With those ever lofty goals in mind....Please don't laugh at me, Haha. Here are the parts I have already acquired and some I plan to acquire in order to meet these goals.

Engine:

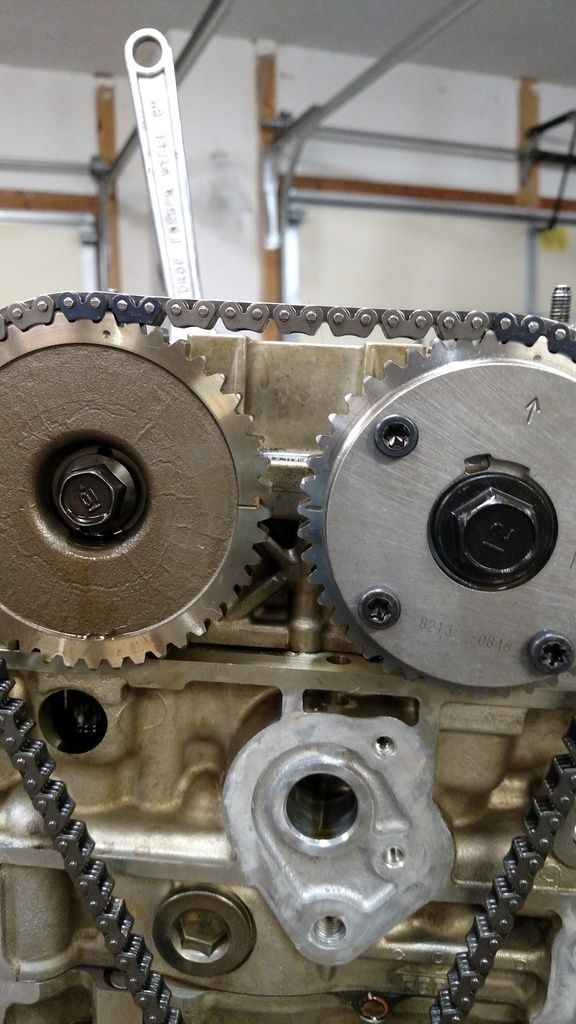

K24A2 out of a TSX

RBC intake from a 06-11 Civic Si

50 degree VTC Actuator

K-tuned Swap Header

Custom 2.5in exhaust

Aftermarket Cruise Control

Kpro V4 Ecu

Custom Engine Harness

Innovate Engine Mounts

Transmission:

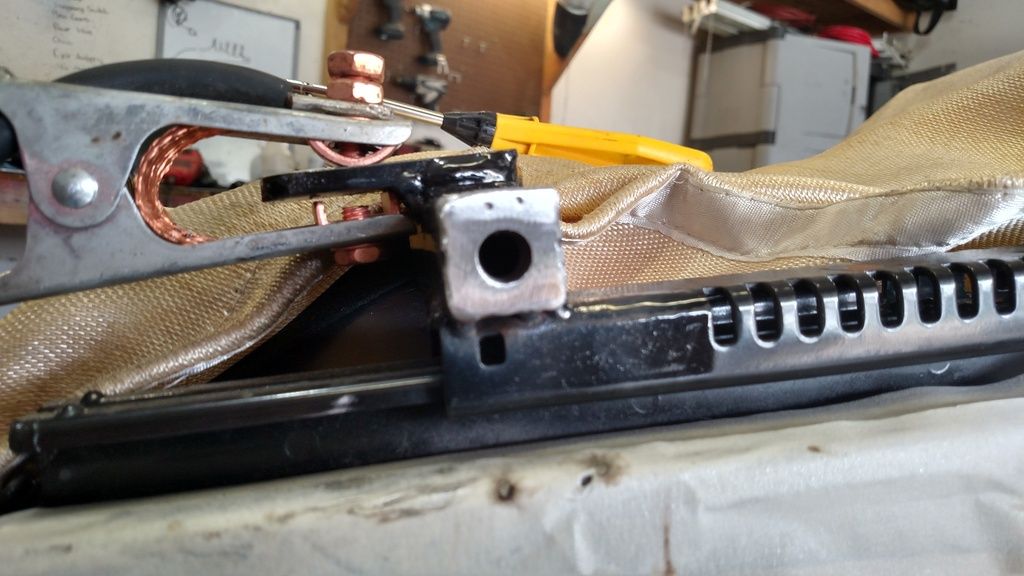

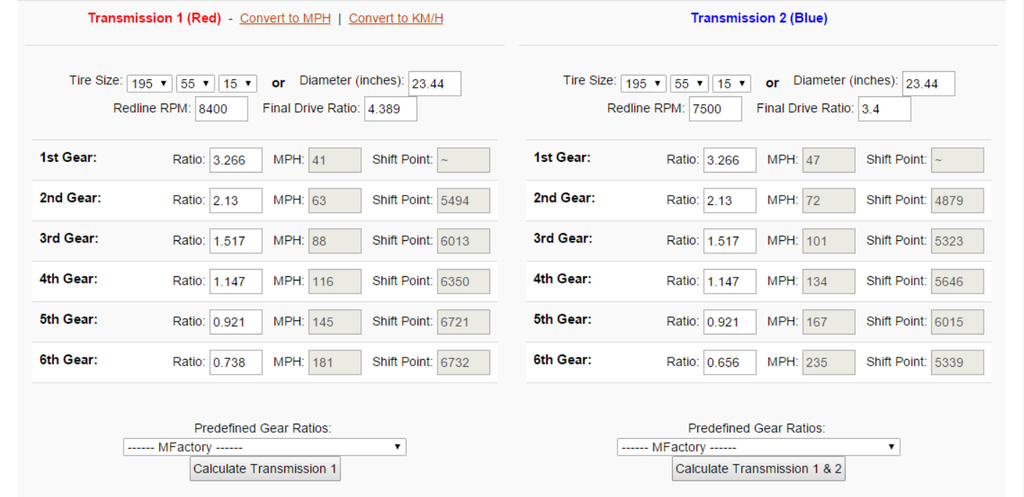

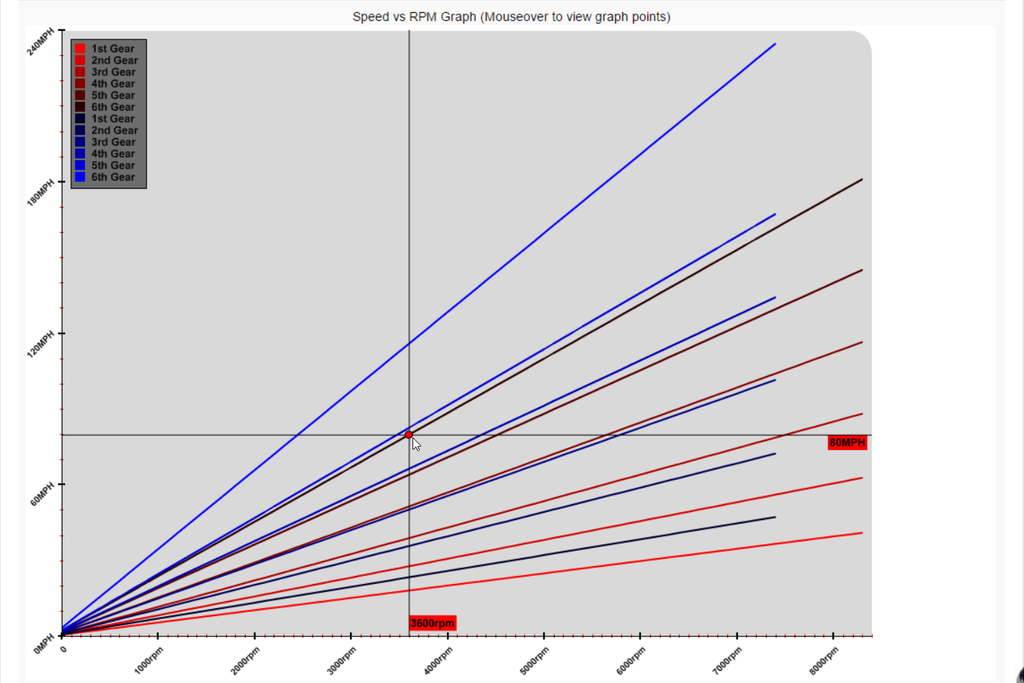

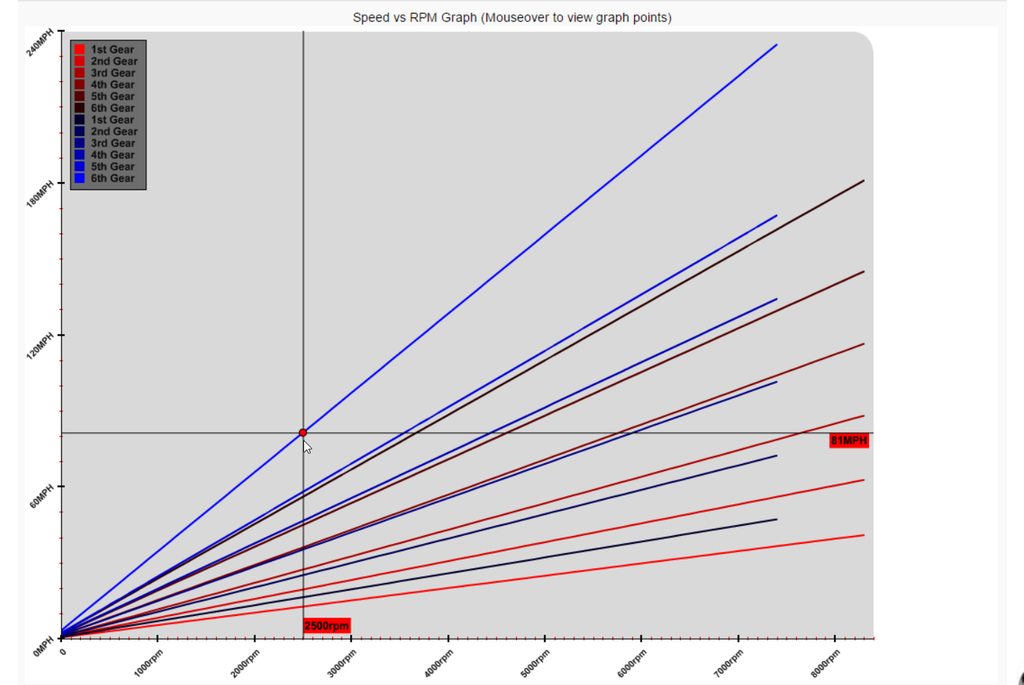

K20 RSX transmission

Custom hardened gear set

Carbon syncros

Stock 06-11 Civic Si LSD

TSX longer 6th gear

Custom 3.4 Final Drive

Suspension:

Custom Fortune Auto front Coilovers with special valving

4K swift springs

Custom front camber plates

Custom swift Rear springs

GAZ rear shocks

Modifed front control arms to accept 02-05 Civic Si ball joint

Custom rear sway bar

Custom front sway bar and mounts

Brakes:

02-05 Civic Si front calipers

Slotted Rotors

Bosch High Performance Pads

Interior:

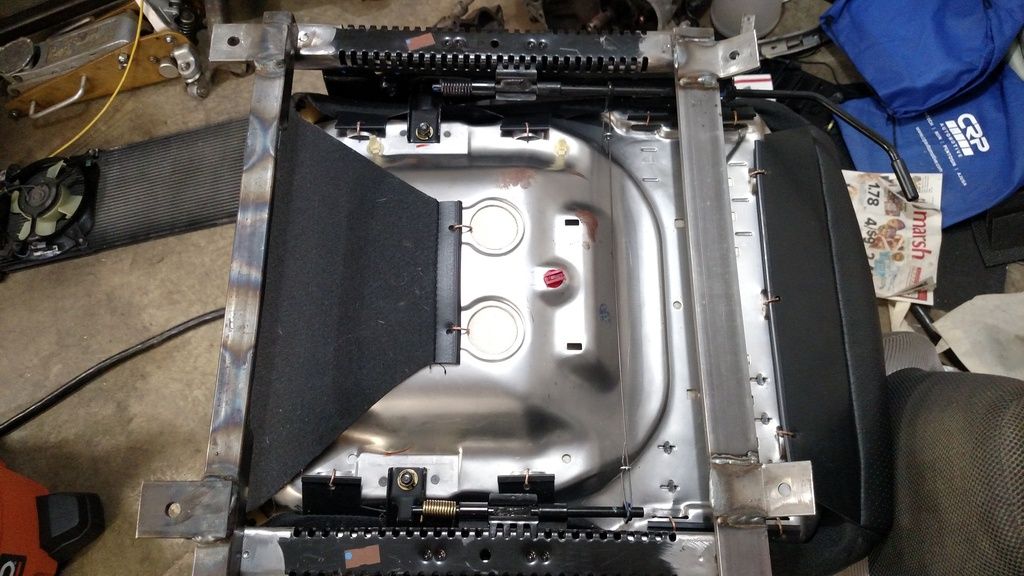

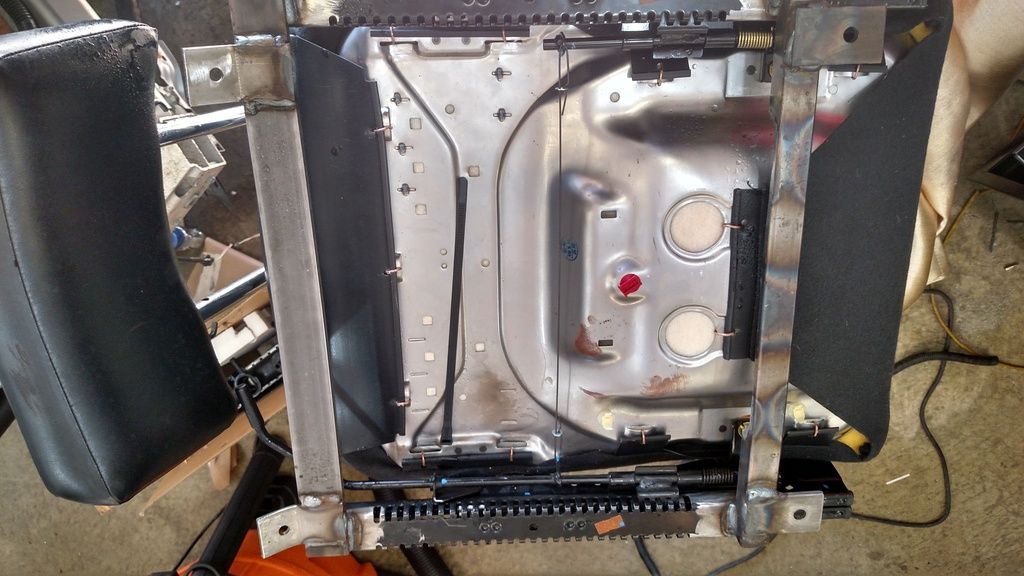

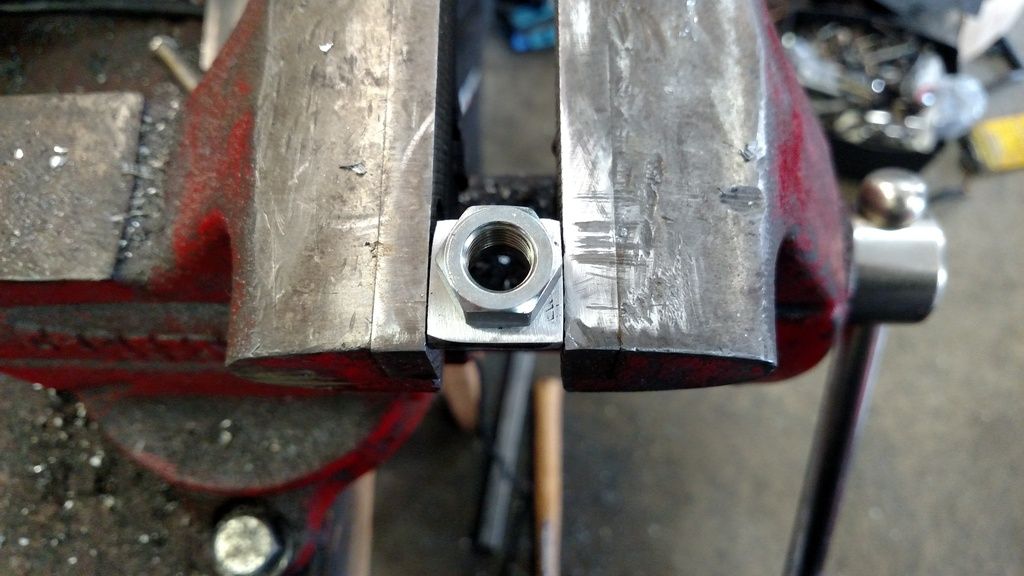

S2000 seats on custom rails

S2000 Steering wheel

S2000 gauge cluster

Custom Infotainment center (Tablet integration)

Window tint primarily for UV protection

Custom rear interior paneling to fill battery hole

500 Watt amp

8 Infinity Speaker Sound System

Battery Relocation to rear

HID Retrofit (not really interior but whatever, it fits no where else)

Wheels and Tires:

Kosei K1 15X7 wheels

200 TW tire, Undecided.

This is my build so far, I would say that I am about 40% of the way through this project as of right now. I have most of the parts on hand and am gathering more and more each day. I just want a great cruising car that will also get great gas mileage. I want it to be at home on the street as it is on the track. I know this is a lofty goal but I think I have the parts and the know how to do it. Even if I don't quite make it there I will still have one fun Insight to mess around in.

Stay Tuned.....

The goal of this project are as follows;

- 12.50 1/4 mile times

- 50-55 MPG on highway trips

- 1G skid pad handling on street tires (RS-3, StarSpecs, Rivels)

- Long distance driving in comfort

- Well integrated Infotainment center

- A/C, Heat, ABS, Power steering are all required.

With those ever lofty goals in mind....Please don't laugh at me, Haha. Here are the parts I have already acquired and some I plan to acquire in order to meet these goals.

Engine:

K24A2 out of a TSX

RBC intake from a 06-11 Civic Si

50 degree VTC Actuator

K-tuned Swap Header

Custom 2.5in exhaust

Aftermarket Cruise Control

Kpro V4 Ecu

Custom Engine Harness

Innovate Engine Mounts

Transmission:

K20 RSX transmission

Custom hardened gear set

Carbon syncros

Stock 06-11 Civic Si LSD

TSX longer 6th gear

Custom 3.4 Final Drive

Suspension:

Custom Fortune Auto front Coilovers with special valving

4K swift springs

Custom front camber plates

Custom swift Rear springs

GAZ rear shocks

Modifed front control arms to accept 02-05 Civic Si ball joint

Custom rear sway bar

Custom front sway bar and mounts

Brakes:

02-05 Civic Si front calipers

Slotted Rotors

Bosch High Performance Pads

Interior:

S2000 seats on custom rails

S2000 Steering wheel

S2000 gauge cluster

Custom Infotainment center (Tablet integration)

Window tint primarily for UV protection

Custom rear interior paneling to fill battery hole

500 Watt amp

8 Infinity Speaker Sound System

Battery Relocation to rear

HID Retrofit (not really interior but whatever, it fits no where else)

Wheels and Tires:

Kosei K1 15X7 wheels

200 TW tire, Undecided.

This is my build so far, I would say that I am about 40% of the way through this project as of right now. I have most of the parts on hand and am gathering more and more each day. I just want a great cruising car that will also get great gas mileage. I want it to be at home on the street as it is on the track. I know this is a lofty goal but I think I have the parts and the know how to do it. Even if I don't quite make it there I will still have one fun Insight to mess around in.

Stay Tuned.....