Tired of that broken driver's side window switch?

Why not print your own replacement switch parts?

The files are open source (with attribution):

View attachment Insight Window Switch.zip

I initially offered these for sale, but have stopped for three reasons:

-Lack of demand; I've only sold a handful of units.

-I'm not making enough to make it worth my trouble at this low volume.

-Too much customer support. Yes, the dashboard has to come out ... Yes, there's a thread on how to do that. No, I won't walk you through it on the phone. *ahem*.

... Yes, there's a thread on how to do that. No, I won't walk you through it on the phone. *ahem*.

I stand behind the product I've already shipped, and will warrant those units in the field, if needed; to date, I haven't had a single return for any 3D printed part I offer.

Here's how to install:

There are two design defects in the driver's side window switch:

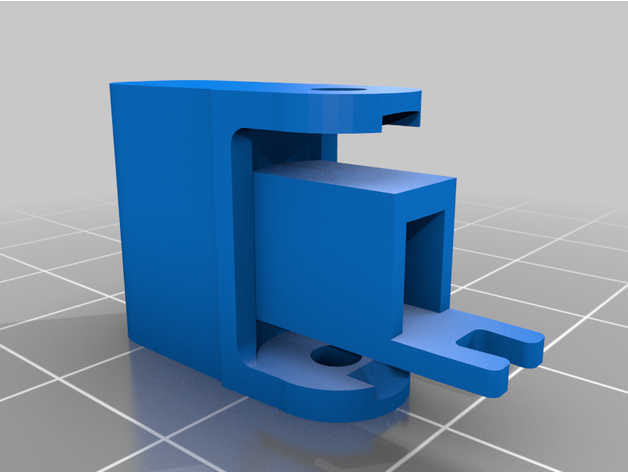

Spring Detent Body: Terribly designed... I imagine this and the trunk latch mechanism were designed by the same intern.

[/url]

The new design is mechanically superior.

-Body thickness increased 30%

-Added a foot that extends down to the PCB; operating the switch now compresses the body, whereas the OEM design experienced shear force (an order of magnitude weaker).

Light Pipe: Also the mechanical linkage that interfaces with the electrical switch.

OEM part is decently designed, except that a light pipe is too brittle to use as a lever, particularly without a hard mechanical stop. The new part is opaque, so the switch will no longer light up at night; VeroClear is the only strong enough clear material and it's only available on high end PolyJet machines... if there's enough demand, we could do a group buy.

Kudos to user Element6 for sending me his broken window switch. Mine isn't actually broken, but I figure this is a fairly common failure that needs fixing.

If you're not comfortable opening up your broken window switch, PM me and we can arrange to ship your entire unit to me; I'll fix it and send it back for $45 (including return shipping CONUS).

Note the feel with 3D printed parts feels softer than OEM - but is still tactile - due to the layering method used in 3D printing. A PolyJet print (group buy) would feel more like OEM, but would also be more expensive.

*You'll likely need a high end 3D printer to resolve these small, dimensionally precise parts. I'm printing drop-in ABS parts on a $30,000 Stratasys SST, but I imagine any machine over $3000 will do a decent job with just a bit of sanding. FYI: Parts printed in PLA won't hold up to the heat/UV.

Why not print your own replacement switch parts?

The files are open source (with attribution):

View attachment Insight Window Switch.zip

I initially offered these for sale, but have stopped for three reasons:

-Lack of demand; I've only sold a handful of units.

-I'm not making enough to make it worth my trouble at this low volume.

-Too much customer support. Yes, the dashboard has to come out

I stand behind the product I've already shipped, and will warrant those units in the field, if needed; to date, I haven't had a single return for any 3D printed part I offer.

Here's how to install:

Spring Detent Body: Terribly designed... I imagine this and the trunk latch mechanism were designed by the same intern.

[/url]

The new design is mechanically superior.

-Body thickness increased 30%

-Added a foot that extends down to the PCB; operating the switch now compresses the body, whereas the OEM design experienced shear force (an order of magnitude weaker).

Light Pipe: Also the mechanical linkage that interfaces with the electrical switch.

OEM part is decently designed, except that a light pipe is too brittle to use as a lever, particularly without a hard mechanical stop. The new part is opaque, so the switch will no longer light up at night; VeroClear is the only strong enough clear material and it's only available on high end PolyJet machines... if there's enough demand, we could do a group buy.

Kudos to user Element6 for sending me his broken window switch. Mine isn't actually broken, but I figure this is a fairly common failure that needs fixing.

If you're not comfortable opening up your broken window switch, PM me and we can arrange to ship your entire unit to me; I'll fix it and send it back for $45 (including return shipping CONUS).

Note the feel with 3D printed parts feels softer than OEM - but is still tactile - due to the layering method used in 3D printing. A PolyJet print (group buy) would feel more like OEM, but would also be more expensive.

*You'll likely need a high end 3D printer to resolve these small, dimensionally precise parts. I'm printing drop-in ABS parts on a $30,000 Stratasys SST, but I imagine any machine over $3000 will do a decent job with just a bit of sanding. FYI: Parts printed in PLA won't hold up to the heat/UV.